The solar panel as one part of the PV system plays the very important role in the whole system,so it is very important to know how to choose the best solar panel for your solar system?

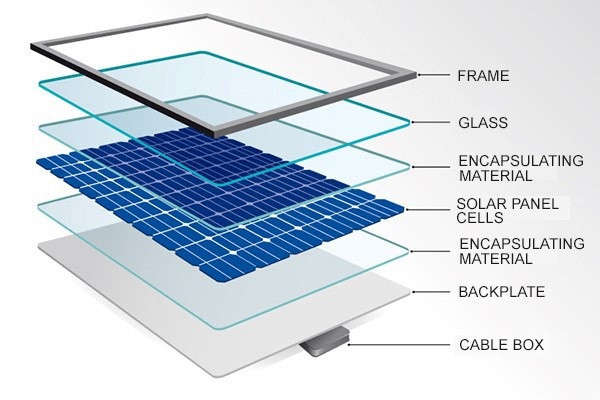

Before we discussed this,we should know well about the layers of the solar panel:

One solar panel is consist of Frame-Glass-EVA-Cells-EVA-Backsheet-Junction box.Do you know which materials are the most important for one solar panel? You may say all materials are important,it is correct.But there are some important materials that you can not distinguish by eyes or by touch.

Glass,Frame,and Junction box(cable and connector) are easy to check by eyes and touch. When you get one solar panel,you need to check the following items:

1)Whether there is any scratch on the frame,glass and backsheet?

2)Whether the frame is strong enough?

3)The inside of the junction box(you can open the cover of the junction box,some junction box is filled with silica gel inside and some was not)

4)Whether the silica gel is well overflow around the edge of the frame and the edge of the junction box?

Cell,EVA, and Backsheet are difficult to check,if you want to check these quality,you need to stay in the factory and check it during the production.

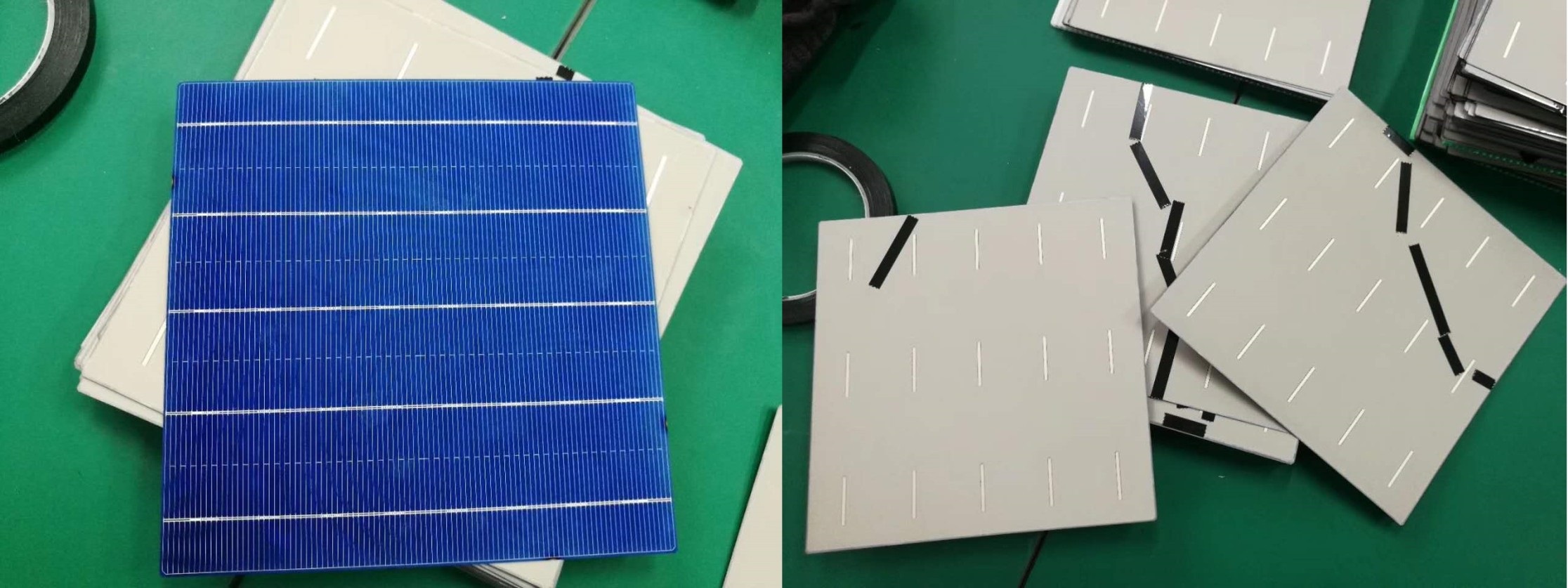

Today we will talk about the solar cells first,before we produce one solar panel,we need to use the flash machine to test the power of the cells and the EL of the cells,then we will classify the cells into different level,Class A;Class B,and Class C. The final solar panel will be A grade,B grade,and C grade in the market.You may ask what's the difference between Class A,Class B and Class C cells?

Class A cells-Perfect cells with the good power and uniform color.

Class B cells-The color is not the same,there is splotch on the cells,or the cells are low power,etc.

Class C cells-Cells with reverse current,cracked cells,low power,big area splotch.etc.

The cost of each cells: Class A>Class B>Class C, the electrical performance for Class A and Class B are both fine,but if your panels are with Class C,that will be big problem in the future,let's see some photos as below:

This is called "Tape cell",some suppliers wanted to get orders from the customers or the customers wanted to buy unreasonable cheap solar panel,then there will be such cells in the market.As you can see the broken cells were jointed by the Tape on the backside,after lamination you will not see the difference from the front cells if you are not care about it.The result of this panel will be damaged soon for sure.

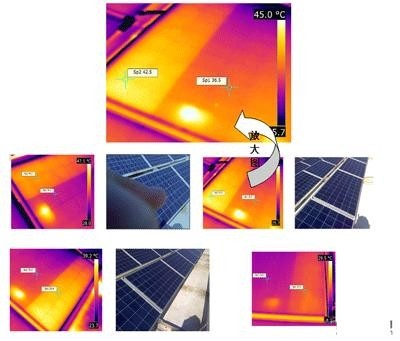

But how to check the cells when you the the solar panels from the supplier? If you have the the infrared thermal imager,it will be easy for you to find out the problem cells

As you can see the photo,it was tested by infrared thermal imager,if there is the cracked cell,the temperature of this cell will be very hot and you need to replace this panel quickly. Some cracked cells are not only Class C cells,it also can happen during production or installation,incorrect installation way also can cause the cracked cells. If you are managing the big solar farm,it is better to use the infrared thermal imager to check all panels when they start to work in the sunshine.

We will talk about the other materials of the solar panels in the future.